SDA Taxanaha aluminium aluminium jilitaanka dhuuban nooca pneumatic dhululubo hawada is haysta caadiga ah nooca

Sharaxaada Alaabta

Dhululubada waa naqshad khafiif ah iyo cabbir yar oo guud, taas oo ku habboon munaasabadaha leh meel xaddidan. Cadaadiskeeda shaqadu inta badan waa inta u dhaxaysa 0.1 ~ 0.9mpa, kaas oo leh hufnaan shaqo oo sarreeya.

Dhululubada taxanaha SDA waxay leeyihiin wax qabad daboolid la isku halayn karo iyo sifooyin dhaqdhaqaaq siman. Waxay qabataa tignoolajiyada wax soo saarka ee saxda ah si loo hubiyo cidhiidhiga iyo saxnaanta dhululubada. Isla mar ahaantaana, dhululubada waxaa lagu qalabeeyaa qalab ilaalin ah, kaas oo yarayn kara saameynta iyo qaylada inta lagu jiro dhaqdhaqaaqa.

Tilmaamaha Farsamada

| Cabbirka Bore (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Habka Ku-simaha | Laba jilitaanka | |||||||||

| Warbaahinta shaqaynaysa | Hawo nadiif ah | |||||||||

| Cadaadiska Shaqada | 0.1 ~ 0.9Mpa (kg/cm) | |||||||||

| Caddaynta Cadaadiska | 1.35Mpa (13.5kgf/cm) | |||||||||

| Heerkulka shaqada | -5 ~ 70 ℃ | |||||||||

| Habka Buffering | leh | |||||||||

| Cabbirka Dekedda | M5 | 1/8 | 1/4 | 3/8 | ||||||

| Qalabka Jirka | Aluminium Aloy | |||||||||

| Dareemayaasha Dareemayaasha | CS1-J | CS1-G CS1-J | ||||||||

Sharaxaadda;SDA100 ilig ama 25in usha biistoonka dhululubada, iyo ilkuhu Ф 32 biistoon

100≤ST <150, oo aan lahayn magnetic, dhererka dhululubada 10.

ST≥150, dhib maleh ama la'aanteed, dhererka dhululubada 10.

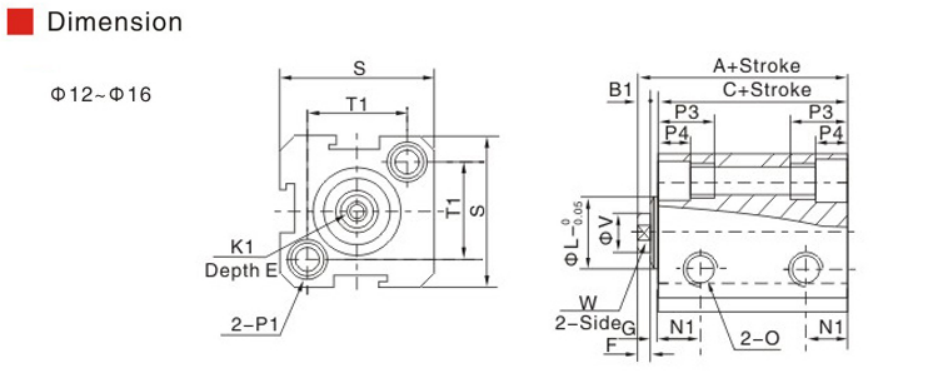

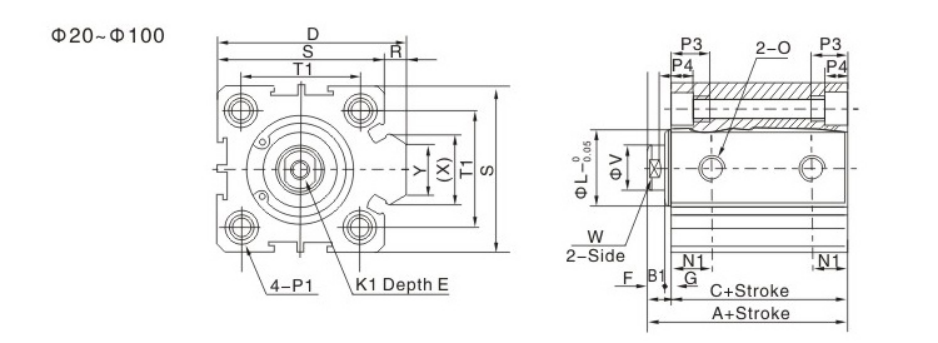

| Cabbirka Bore (mm) | Nooca caadiga ah | Nooca Magnet | D | B1 | E | F | G | K1 | L | N1 | N2 | O | ||

| A | C | A | C | |||||||||||

| 12 | 22 | 17 | 32 | 27 | / | 5 | 6 | 4 | / | M3X0.5 | / | 7.5 | 5 | M5X0.8 |

| 16 | 24 | 18.5 | 34 | 28.5 | / | 5.5 | 6 | 4 | 1.5 | M3X0.5 | 11 | 8 | 5.5 | M5X0.8 |

| 20 | 25 | 19.5 | 35 | 29.5 | 36 | 5.5 | 8 | 4 | 1.5 | M4X0.7 | 14 | 9 | 5.5 | M5X0.8 |

| 25 | 27 | 21 | 37 | 31 | 42 | 6 | 10 | 4 | 2 | M5X0.8 | 17 | 9 | 5.5 | M5X0.8 |

| 32 | 31.5 | 24.5 | 41.5 | 34.5 | 50 | 7 | 12 | 4 | 3 | M6X1 | 22 | 9 | 9 | G1/8 |

| 40 | 33 | 26 | 43 | 36 | 58.5 | 7 | 12 | 4 | 3 | M8X1.25 | 28 | 9.5 | 7.5 | G1/8 |

| 50 | 37 | 28 | 47 | 38 | 71.5 | 9 | 15 | 5 | 4 | M10X1.5 | 38 | 10.5 | 10.5 | G1/4 |

| 63 | 41 | 32 | 51 | 42 | 84.5 | 9 | 15 | 5 | 4 | M10X1.5 | 40 | 12 | 11 | G1/4 |

| 80 | 52 | 41 | 62 | 51 | 104 | 11 | 20 | 6 | 5 | M14X1.5 | 45 | 14.5 | 14.5 | G3/8 |

| 100 | 63 | 51 | 73 | 61 | 124 | 12 | 20 | 7 | 5 | M18X1.5 | 55 | 17 | 17 | G3/8 |

| Cabbirka Bore (mm) | P1 |

| 12 | Dhinac labajibbaaran: Ф6.5 ThreadM5 * 0.8 Iyadoo dalool Ф4.2 |

| 16 | Dhinac labajibbaaran: Ф6.5 ThreadM5 * 0.8 Iyadoo dalool Ф4.2 |

| 20 | Dhinac labajibbaaran:Ф 6.5 ThreadM5*0.8 Godka loo maro Ф4.2 |

| 25 | Dhinac labajibbaaran:Ф 8.2 ThreadM6*1.0 Godka loo maro Ф4.6 |

| 32 | Dhinac labajibbaaran:Ф 8.2 ThreadM6*1.0 Godka loo maro Ф4.6 |

| 40 | Dhinac labajibbaaran: Ф10 ThreadM6 * 1.25 Godka Ф6.5 |

| 50 | Dhinac labajibbaaran: Ф11 ThreadM6 * 1.25 Godka Ф6.5 |

| 63 | Dhinac labajibbaaran: Ф11 ThreadM8*1.25 Godka Ф6.5 |

| 80 | Dhinaca labanlaaban: Ф14 ThreadM12*1.75 Godka e: Ф9.2 |

| 100 | Dhinac labajibbaaran: Ф17.5 ThreadM14*12 Godka loo maro Ф11.3 |

| Cabbirka Bore (mm) | P3 | P4 | R | S | T1 | V | W | X | Y |

| 12 | 12 | 4.5 | / | 25 | 16.2 | 6 | 5 | / | / |

| 16 | 12 | 4.5 | / | 29 | 19.8 | 6 | 5 | / | / |

| 20 | 14 | 4.5 | 2 | 34 | 24 | 8 | 6 | 11.3 | 10 |

| 25 | 15 | 5.5 | 2 | 40 | 28 | 10 | 8 | 12 | 10 |

| 32 | 16 | 5.5 | 6 | 44 | 34 | 12 | 10 | 18.3 | 15 |

| 40 | 20 | 7.5 | 6.5 | 52 | 40 | 16 | 15 | 21.3 | 16 |

| 50 | 25 | 8.5 | 9.5 | 62 | 48 | 20 | 17 | 30 | 20 |

| 63 | 25 | 8.5 | 9.5 | 75 | 60 | 20 | 17 | 28.7 | 20 |

| 80 | 25 | 10.5 | 10 | 94 | 74 | 25 | 22 | 36 | 26 |

| 100 | 30 | 13 | 10 | 114 | 90 | 25 | 22 | 35 | 26 |