SC Taxanaha aluminium aluminium jilitaanka dhululubo hawada pneumatic caadiga ah oo leh deked

Sharaxaada Alaabta

Mabda'a shaqada ee silsiladaha taxanaha SC waa in la isticmaalo xoogga cadaadiska hawada si loogu riixo piston si uu ugu dhaqaaqo dhululubada. Marka cadaadiska hawada lagu daro hal deked oo dhululubo ah, piston-ka ku jira dhululubada wuxuu ku dhaqaaqaa cadaadis, sidaas darteed riixaya qalabka farsamada ee ku xiran piston. Iyadoo la xakameynayo soo-gelinta iyo ka-soo-saarka cadaadiska hawada, dhaqdhaqaaq laba jiho ah ama mid jiho ah ayaa la xaqiijin karaa.

Dhululubada noocaan ah waxay dooran kartaa laba jilid ama qaab jilid iyadoo loo eegayo baahida dhabta ah. Habka laba jilitaanka, dhululubada ayaa horay iyo gadaal u socon karta iyadoo la raacayo ficilka cadaadiska hawada; Habka hal-abuurka ah, dhululubada kaliya waxay ku dhaqaaqi kartaa cadaadiska hal dhinac, dhinaca kalena wuxuu dib u dejin karaa piston-ka iyada oo loo marayo xoogga soo noqoshada ee guga.

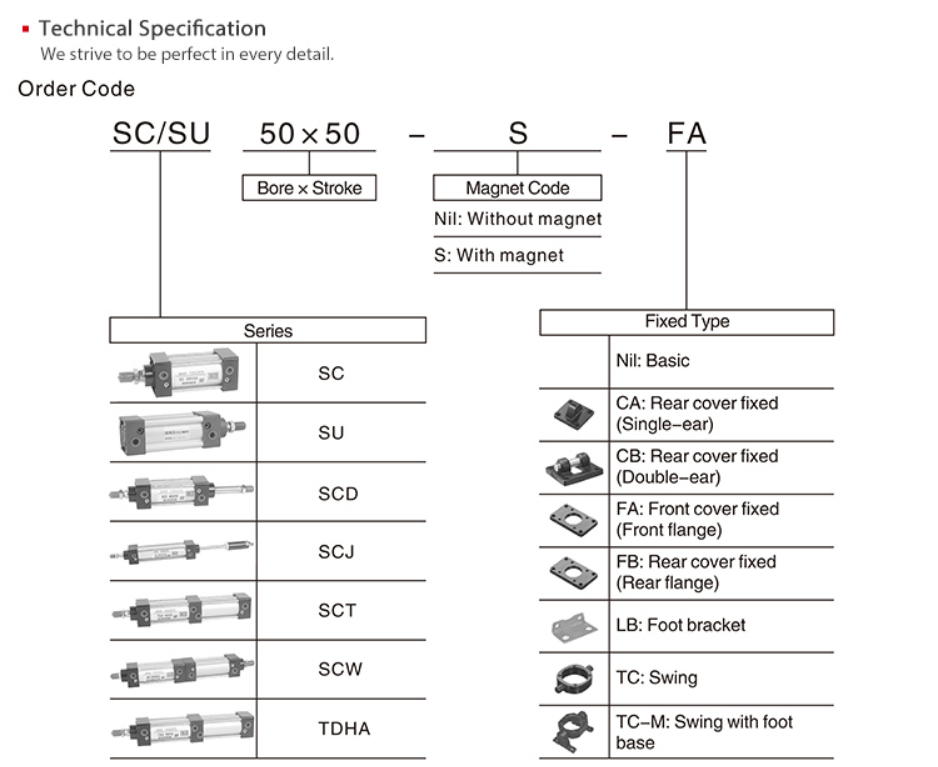

Tilmaamaha Farsamada

| Cabbirka Bore (mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 |

| Habka Ku-simaha | Laba jilitaanka | |||||||||

| Warbaahinta shaqaynaysa | Hawo nadiif ah | |||||||||

| Cadaadiska Shaqada | 0.1 ~ 0.9Mpa (1 ~ 9kgf/cm2) | |||||||||

| Caddaynta Cadaadiska | 1.35MPa (13.5kgf/cm2) | |||||||||

| Qiyaasta heerkulka shaqada | -5 ~ 70℃ | |||||||||

| Habka Buffering | la hagaajin karo | |||||||||

| Fogaanta hakinta (mm) | 13-18 | 22 | 25-30 | |||||||

| Cabbirka Dekedda | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | ||||

| Qalabka Jirka | Aluminium Aloy | |||||||||

| Dareemayaasha Dareemayaasha | CS1-F CS1-U SC1-G DMSG | |||||||||

| Saldhig go'an ee Dareemayaasha | F-50 | F-63 | F-100 | F-125 | F-160 | F-250 | ||||

Stroke Of Silinder

| Cabbirka Bore (mm) | Istaroogga caadiga ah (mm) | Max. Faalig (mm) | Faalig la Ogol yahay (mm) | |||||||||

| 32 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1000 | 2000 |

| 40 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 50 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 63 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 80 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 100 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 125 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 160 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 200 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 250 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

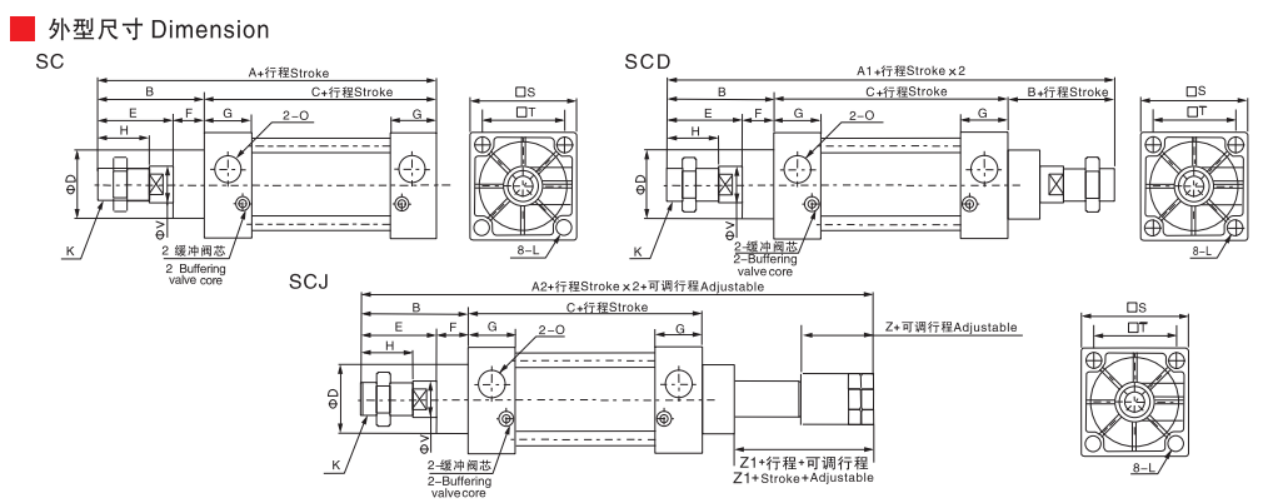

| Cabbirka Bore (mm) | A | A1 | A2 | B | C | D | E | F | G | H | K | L | O | S | T | V |

| 32 | 140 | 187 | 185 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | M10x1.25 | M6x1 | G1/8 | 45 | 33 | 12 |

| 40 | 142 | 191 | 187 | 49 | 93 | 32 | 34 | 15 | 27.5 | 24 | M12x1.25 | M6x1 | G1/4 | 50 | 37 | 16 |

| 50 | 150 | 207 | 197 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M6x1 | G1/4 | 62 | 47 | 20 |

| 63 | 152 | 209 | 199 | 57 | 95 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M8x1.25 | G3/8 | 75 | 56 | 20 |

| 80 | 183 | 258 | 242 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G3/8 | 94 | 70 | 25 |

| 100 | 189 | 264 | 248 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G1/2 | 112 | 84 | 25 |

| 125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |

| 160 | 239 | 352 | 332 | 113 | 126 | 62 | 88 | 25 | 38 | 72 | M36x2 | M16x2 | G3/4 | 174 | 134 | 40 |

| 200 | 244 | 362 | 342 | 118 | 126 | 62 | 88 | 30 | 38 | 72 | M36x2 | M16x2 | G3/4 | 214 | 163 | 40 |

| 250 | 294 | 435 | 409 | 141 | 153 | 86 | 106 | 35 | 48 | 84 | M42x2 | M20x2.5 | PT1 | 267 | 202 | 50 |

| SQC125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |